Remember extra consideration during break in will result in longer packing life.

Fire pump packing leaking.

Overtightening is the most common cause of packing failure.

Packing failure can cause pump damage pump failure and unscheduled plant shutdowns not to mention the cleanup effort.

More water is brought to the packing than can be absorbed.

Follow these two steps.

If you have any questions about replacing fire pump packing or would prefer we perform the service for you simply pick up the phone and call us at 302 652 4722.

For most braided pump packing liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface and ensure the seal s long life.

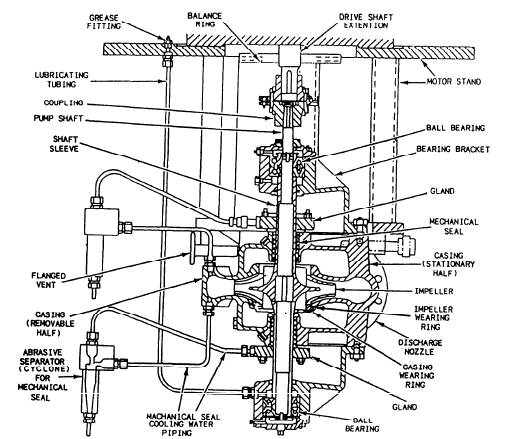

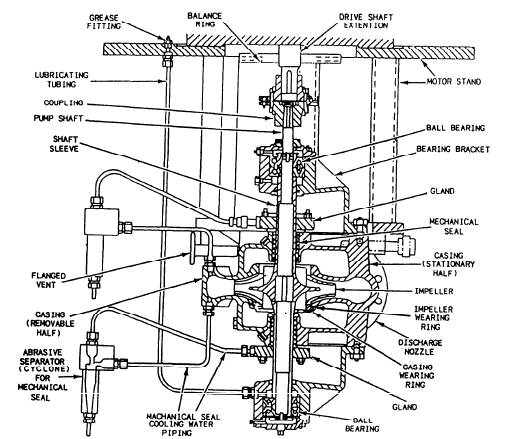

Feel the packing gland be careful of the rotating shaft to see if the packing gland is too hot or uneven which will result in damage to the pump shaft.

When adjusting pump packing the goal is to arrive at the lowest acceptable leak rate while maintaining thermal equilibrium.

Packing adjustment will be more frequent at first.

Considering the potential cost impact keeping compression packing functioning properly may well be the most critical factor ensuring that the pump keeps working.

The amount of leakage is controlled by the packing gland d.

Start the pump and allow the packing to leak freely at start up.

During normal operation of the fire pump the excess water will drip from the pump.

Adjust the followers one flat or of a turn every 30 minutes or until the leakage is controlled.

During the break in period adjustments should be made gradually one flat at a time allowing 5 to 10 minutes between adjustments.

You ll be confident that your system is ready to operate with real time monitoring and the added benefit of alerts and alarms notifications that you can configure.

Our blog today looks at the proper procedures for packing gland adjustments which will help extend the service life of your fire pump.

When compression packing fails the consequences can be devastating.

Tighten down the followers.

The packing gland should be placed on top of the packing.

Peerless fireconnect allows you to access complete fire pump system information 24 7 anytime and anywhere via your smartphone tablet laptop or desktop.